touchskin Demonstrator

- User interface with proximity sensor, touch operation, and illuminated areas

- High light density of > 1,500 cd/m² and homogeneous illumination

- Less than 2 mm thin and ultra light due to special plastic electronic technology

- The adhesive foil allows the combination with any suitable surface

What you can use the touchskin demonstrator for

Check quality

Convince yourself in a very simple way of the performance of plastic electronic technology. Of the quality of the touch operation. Of the light density and homogeneity of the light fields.

Convince others

You will convince your customers and decision makers of your idea of smart surfaces. Just put the demonstrator on the table and let the others experiment with it. The ideas will then come all by themselves.

Make your own beautiful and smart interface

You have a beautiful translucent surface material. Use the demonstrator to test how you can also use this material as a smart surface with touch operation and lighting.

What the touchskin demonstrator consists of

The demonstrator consists of

- the user interface (120 x 55 x 1.75 mm)

- and a battery holder for 2 Mignon (AA) batteries with on/off switch.

The user interface includes:

- 3 light areas 28 x 11 mm

- 3 light areas 11 x 11 mm

- 6 touch buttons (each light area is a touch button)

- 1 proximity sensor

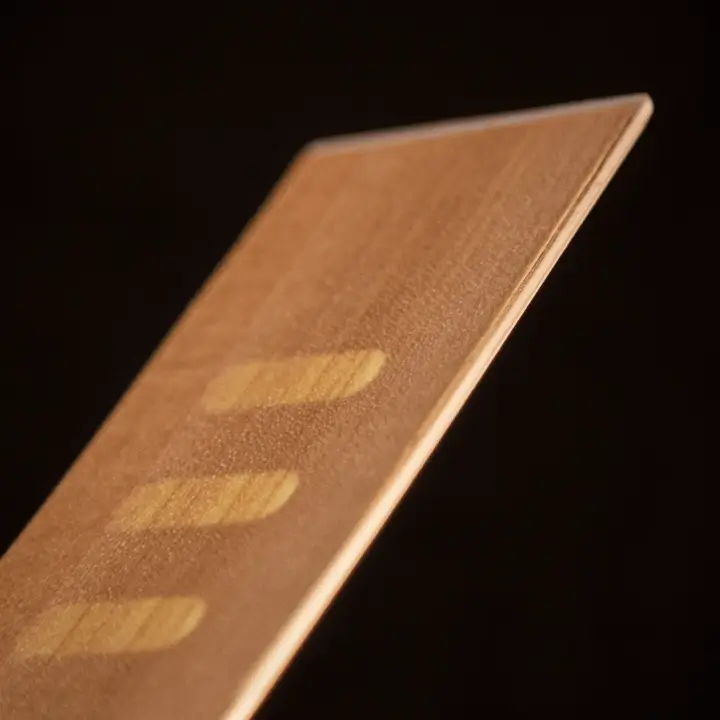

The Layer Stack

Find out what quality of light is contained in a structure that is not even 2mm thin

Homogeneous illumination of the light areas with one side LED each by means of special light guides and diffuser films.

No overshining between the individual light areas due to the use of opaque light separators between the light guides.

No LED hotspots due to a completely light-tight blackout film. The light emerges only at the desired locations of the luminous fields.

Combine the touchskin demonstrator with any suitable surface

No conductive materials

Materials such as plastics, wood or glass are suitable. It should be noted that the surface must have no or only very low conductivity. Conductive surfaces (e.g. made of metal) would act like a shield layer and make the touch application impossible.

Translucent areas

The surface must be translucent at those points of the user interface where the lighting elements are located. In the translucent areas, the color, density and homogeneity of the light can be influenced by the surface. The translucent areas can also be designed so that they are only visible when the lighting is activated (black panel effect).

Printed decorative films

The greatest design diversity is achieved by using printed decorative films. Mostly transparent film materials such as PMMA, PC or PET are used for this purpose, which are printed either on the rear side (back glass) or on the front side (front glass) using screen printing or other printing processes. Both matte and glossy or high-gloss surfaces can be realized.

Surface finishing

Depending on requirements, the surface can be additionally coated with a transparent protective coating (e.g. hard coat) or a transparent plastic (e.g. transparent thermoplastic or PU). This improves the surface properties (mechanical or chemical resistance, anti-fingerprint).

How to operate the touchskin demonstrator?

- The demonstrator is switched on with the on/off switch on the battery holder. All light areas are unlit.

- The demonstrator is activated by bringing the hand closer to the control unit. Only the light area near the On button is illuminated.

- Touching the On button illuminates all light areas.

- Touching the up/down buttons switches between bright and dimmed illumination of the light areas.

- Touching the large light areas switches them off.